Supply Stream

Bridge the gap between production demand and plant capability with dynamic scheduling and supply visibility.

Optimize Schedules

Maintain Product Records

Coordinate Outages

Configure Shifts and Crews

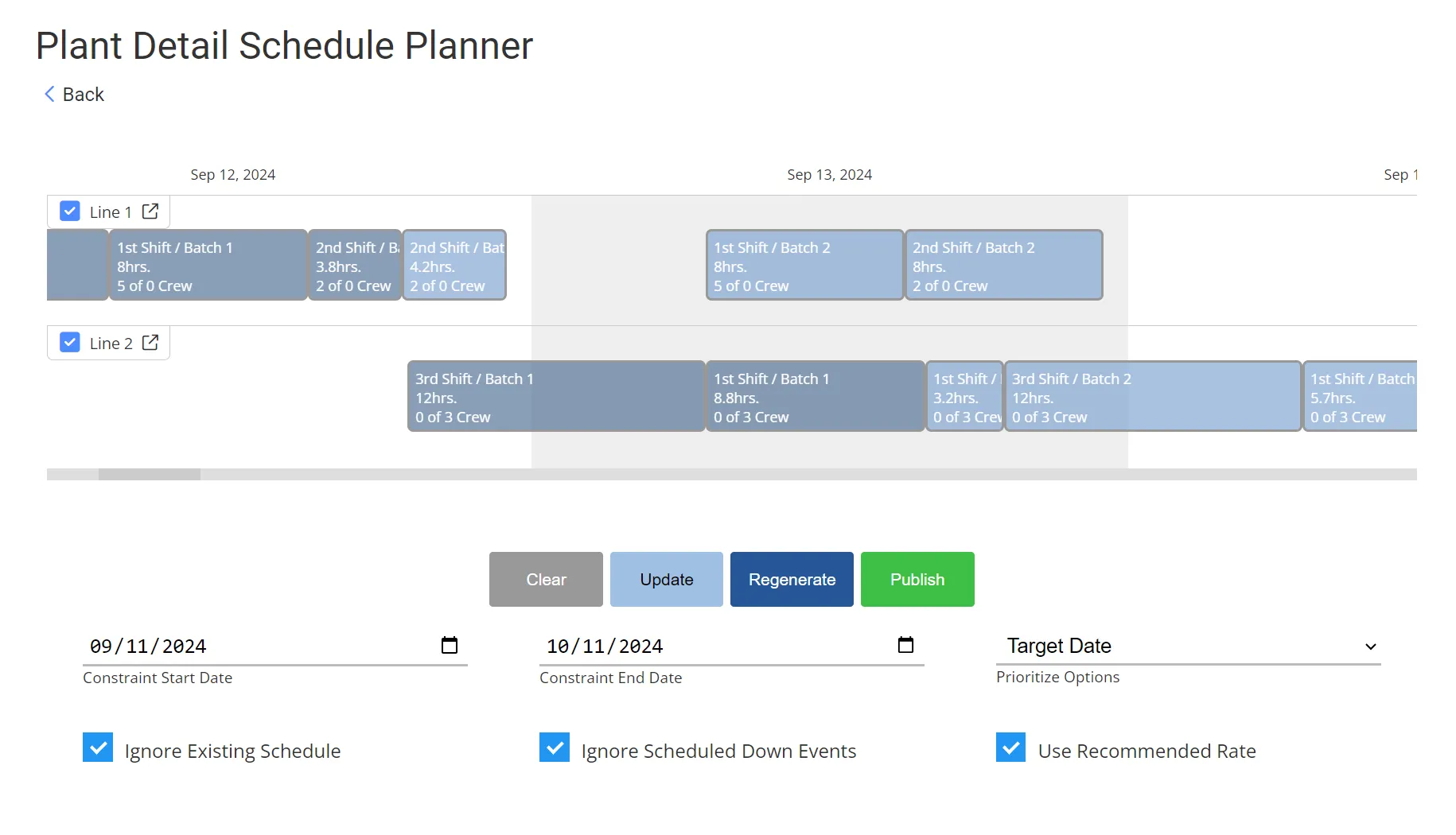

Line Scheduling Made Easy

Visualize and update line schedules based on current constraints, product demand, shift patterns, and planned outages. Adjust in real time and regenerate forward-looking plans in seconds.

MODULE COMBINATIONS

When paired with modules that manage the who, what, and when of plant operations, Supply Stream becomes a fully connected planning tool that adjusts to real-world conditions.

People

Connecting supply stream with the people module helps align staffing plans, team vacation calendars, and skill blocks with shift-based production needs. This can keep your production lines on schedule with knowledge of availability and absences.

Inventory

Connecting to the inventory module helps Supply Stream keep production plans in sync with what’s available. It adds visibility to material status so teams can schedule with fewer surprises and avoid planning around parts that aren’t there yet.

Autonomous Maintenance

Integrate supply planning with autonomous maintenance schedules to ensure operator-led equipment care aligns with production demands. Coordinate cleaning, lubrication, and inspection routines with supply stream timing to maximize both equipment reliability and production efficiency.