Inventory

Manage materials across your operation with real-time tracking, automated receipts, ERP integration, and comprehensive reporting for complete visibility and control.

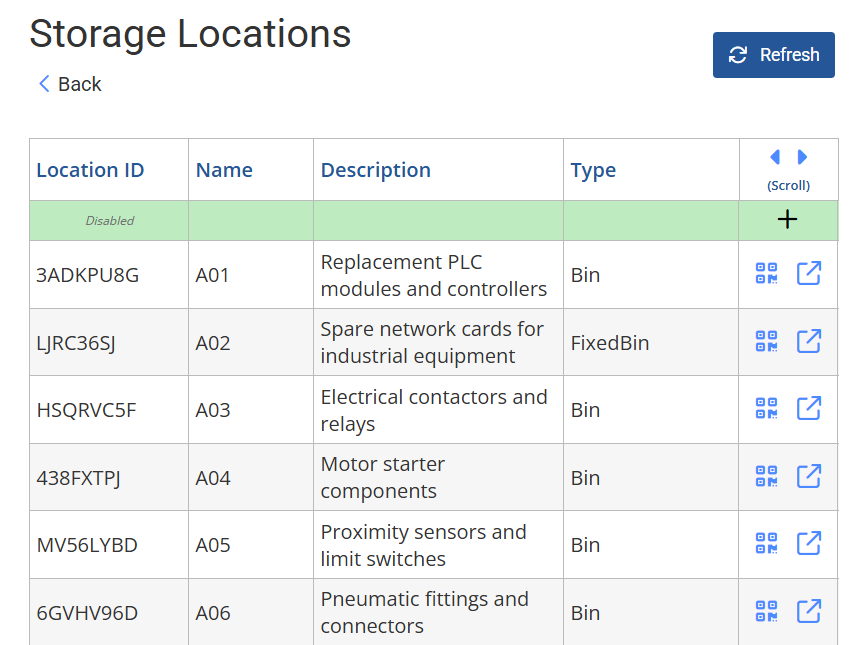

Track Locations

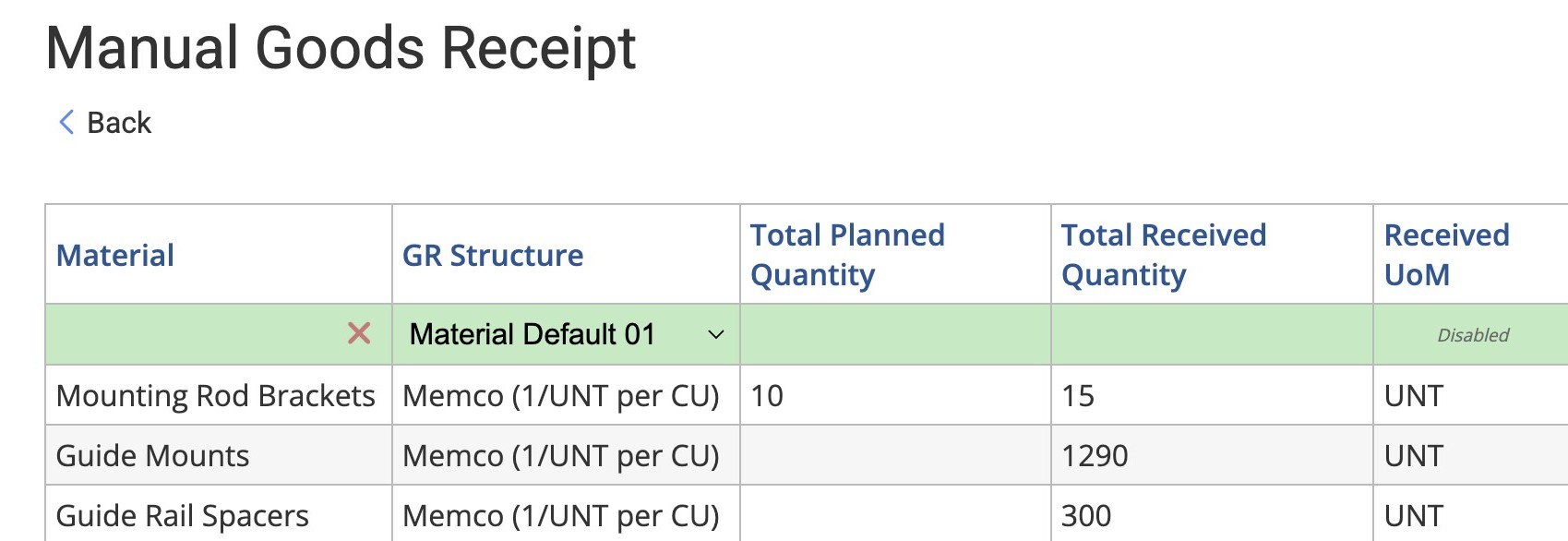

Goods Receipt

Costing Reports

ERP Integration

Goods Receipt & Put-Away Guidance

Process goods receipts efficiently with automated put-away instructions based on pre-defined storage location rules. Guide warehouse personnel to optimal locations based on material type, storage requirements, and available space.

Multi-Location Inventory Tracking

Track different inventory types across multiple storage locations throughout your facility. Monitor raw materials, work-in-process, finished goods, and consumables with location-specific rules and reporting capabilities.

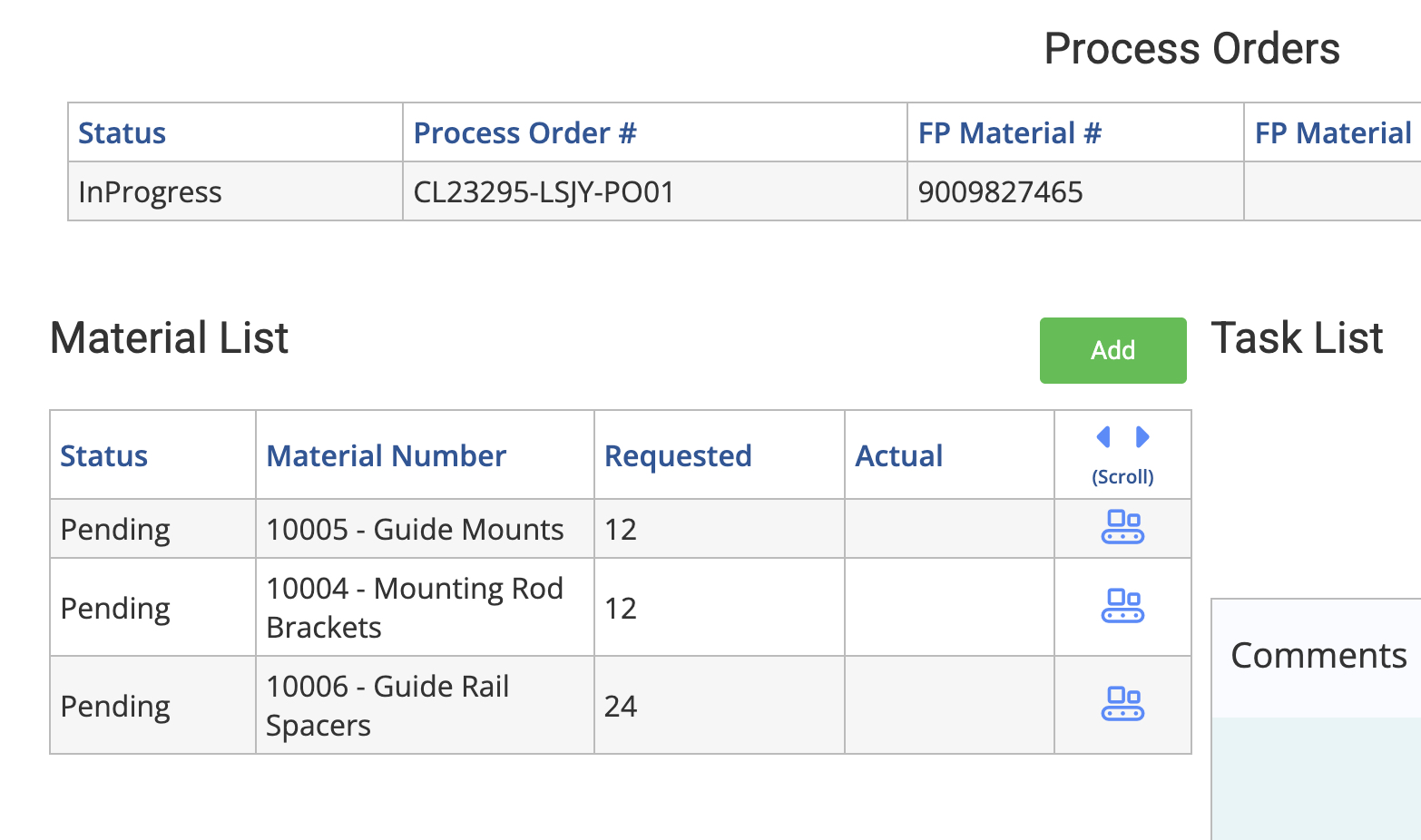

Production Integration & Consumption

Record production results and material consumptions automatically. Track what materials go into each production run, monitor yield rates, and maintain accurate inventory balances as production progresses.

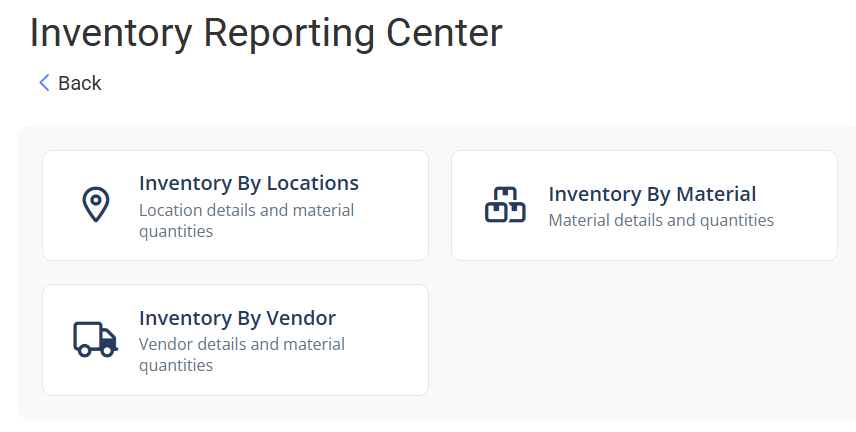

ERP Integration & Reporting

Interface seamlessly with external ERP systems to relay quantity updates throughout operational processes. Generate costing reports based on quantities on hand, run valuation analyses, and maintain synchronized inventory records across systems.

MODULE COMBINATIONS

Inventory management integrates with other modules to ensure materials flow efficiently through your operation with accurate tracking and timely availability.

Preventative Maintenance

Provide maintenance teams with instant visibility into parts availability and location. Know immediately if a needed part is in stock, where to find it, and eliminate time wasted searching for materials during equipment repairs.

Operations

Record production results and material consumptions directly through operations. Track what materials are used during each operational activity, monitor consumption rates, and maintain accurate inventory balances as operations progress.

Production Execution

Know exactly what inventory is required for each production task. Access real-time information on part locations and availability before starting work, ensuring teams have the materials they need when they need them.