Safety

Safety isn’t paperwork. It’s visibility. It’s culture. It’s action. The Safety module transforms safety from a program into a standard — turning reports and observations into a live picture of risk. With predictive insight, teams gain visibility, accountability, and the power to act before incidents happen.

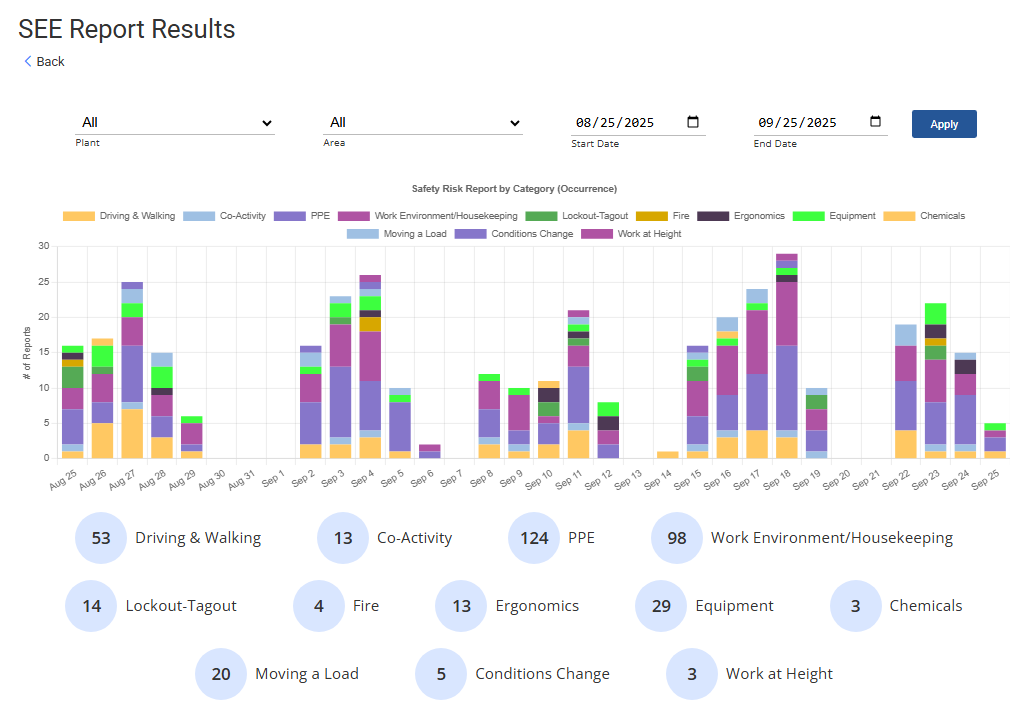

Predictive Risk Visibility

Proactive Safety Culture

Integrated Reporting and Actions

Centralized Safety Standards

Weak Signal Reporting

Identify and categorize unsafe acts and conditions by area to spotlight where your next incident is most likely to occur.

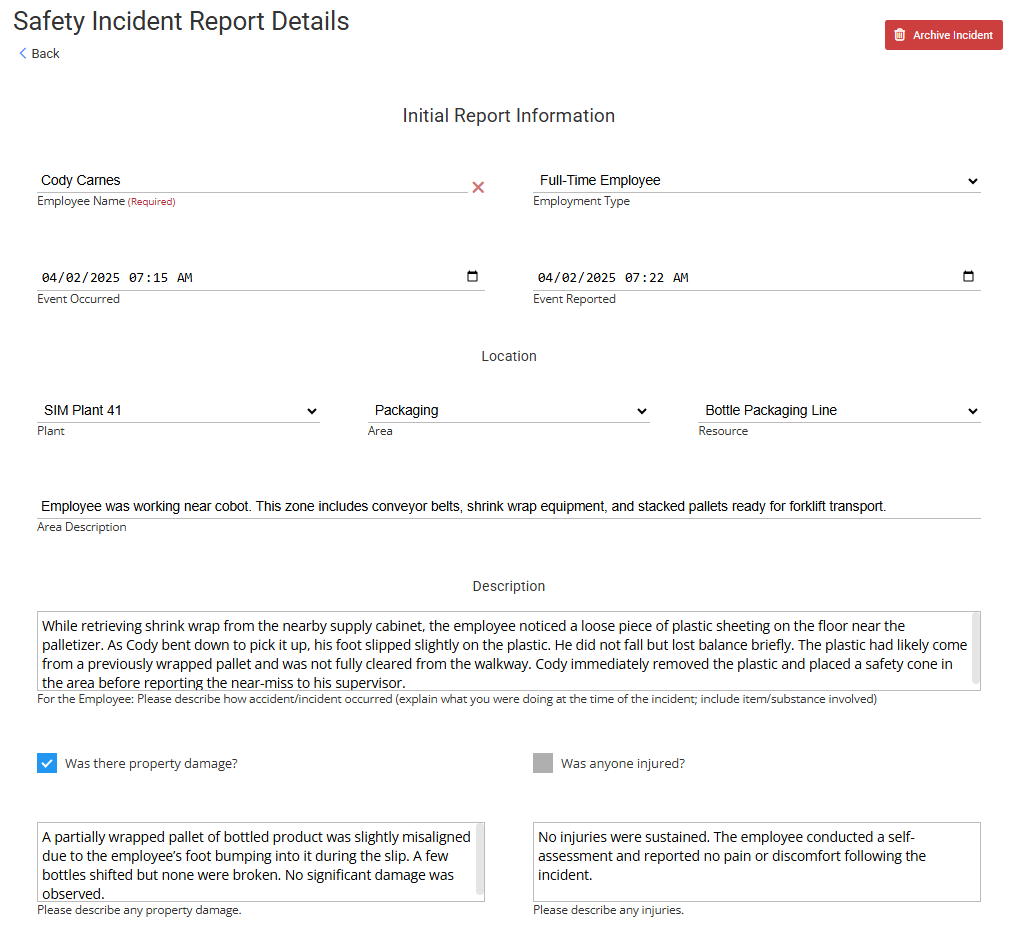

Incident Reporting

Log and investigate all incidents with built-in root cause analysis and action planning — ensuring focus on prevention, not just reaction.

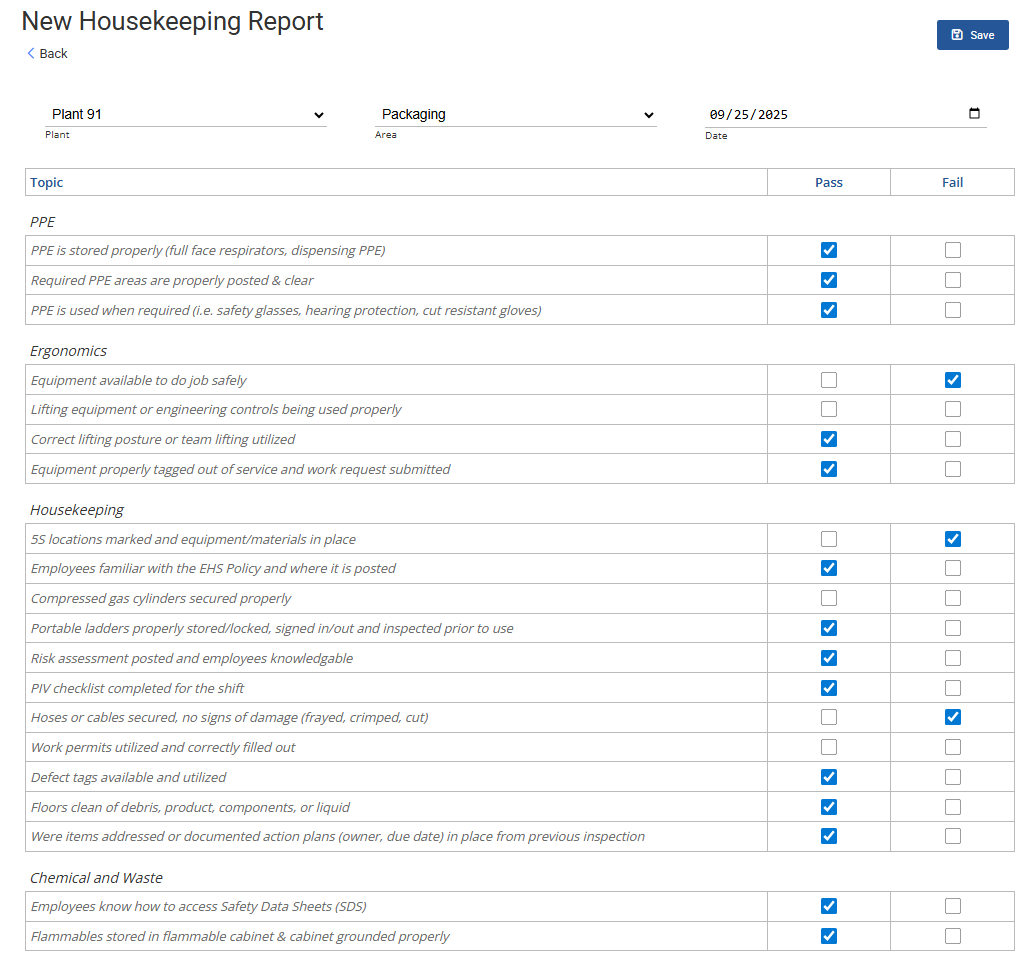

HSE Inspections

Reinforce expectations through structured audits that prompt reflection, drive accountability, and combat complacency.

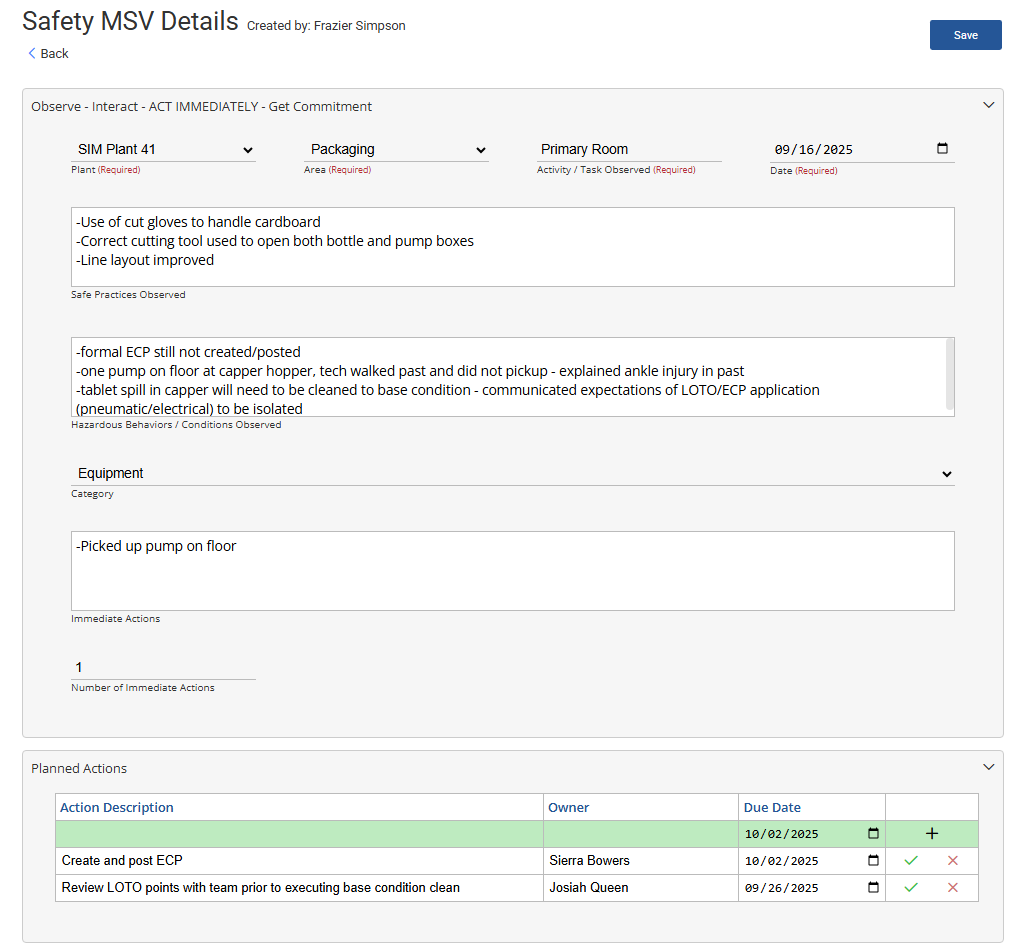

Managerial Safety Visits

Equip leaders to walk the floor with purpose and surface risks that forms and dashboards can’t catch.

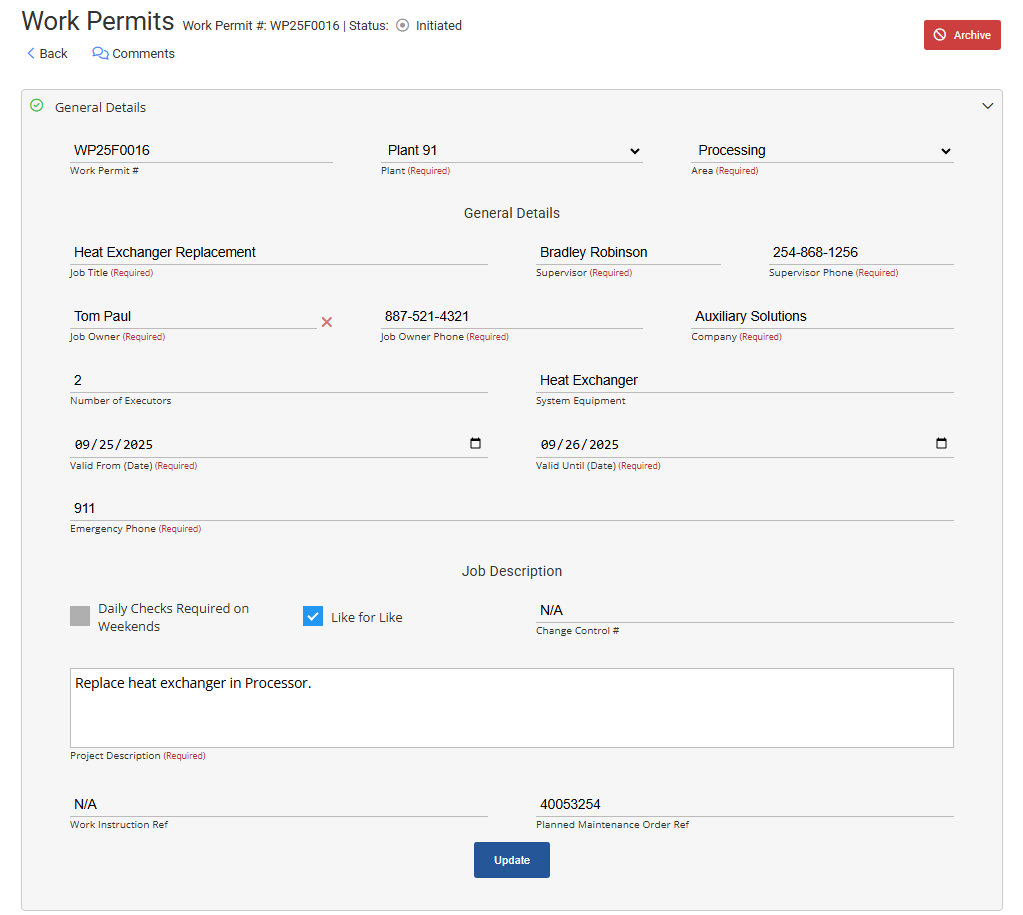

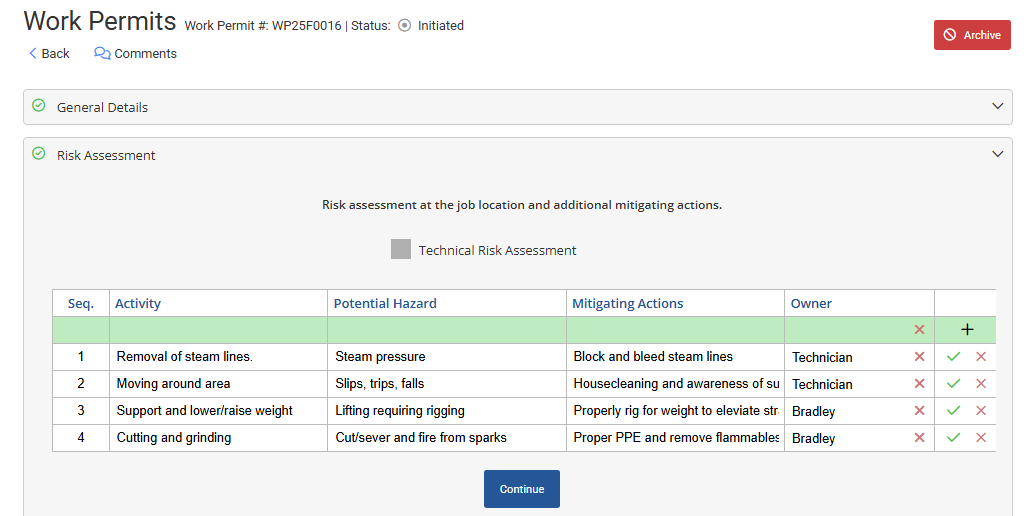

Work Permits

Digitize and control high-risk tasks with clear workflows and visibility into active authorizations.

Safety Knowledge Base

Centralize JSAs, lockout/tagout procedures, and safety SOPs in one accessible, always up-to-date hub.

MODULE COMBINATIONS

Safety management integrates with operational and improvement modules to embed safety considerations into all aspects of plant operations and continuous improvement initiatives.

Operations

Embed safety protocols into all operational activities. Ensure safety considerations are integrated into work planning, risk assessments are conducted for all activities, and safety performance is monitored continuously.

Action Planning

Convert safety incidents and observations into systematic improvement plans. Use structured problem-solving to address safety risks, implement preventive measures, and drive safety culture improvements.