Autonomous Maintenance

Standardization is the foundation of reliability. Plant Toolbox drives operational excellence through proven processes that lock in equipment base conditions, streamline equipment setups and changeovers, and empower teams to act on early warning issues before they become catastrophic failures.

Equipment Setup Standards

Scheduled CIL Tasks

Defect Reporting

Standardized Changeover Execution

Central Knowledge Base

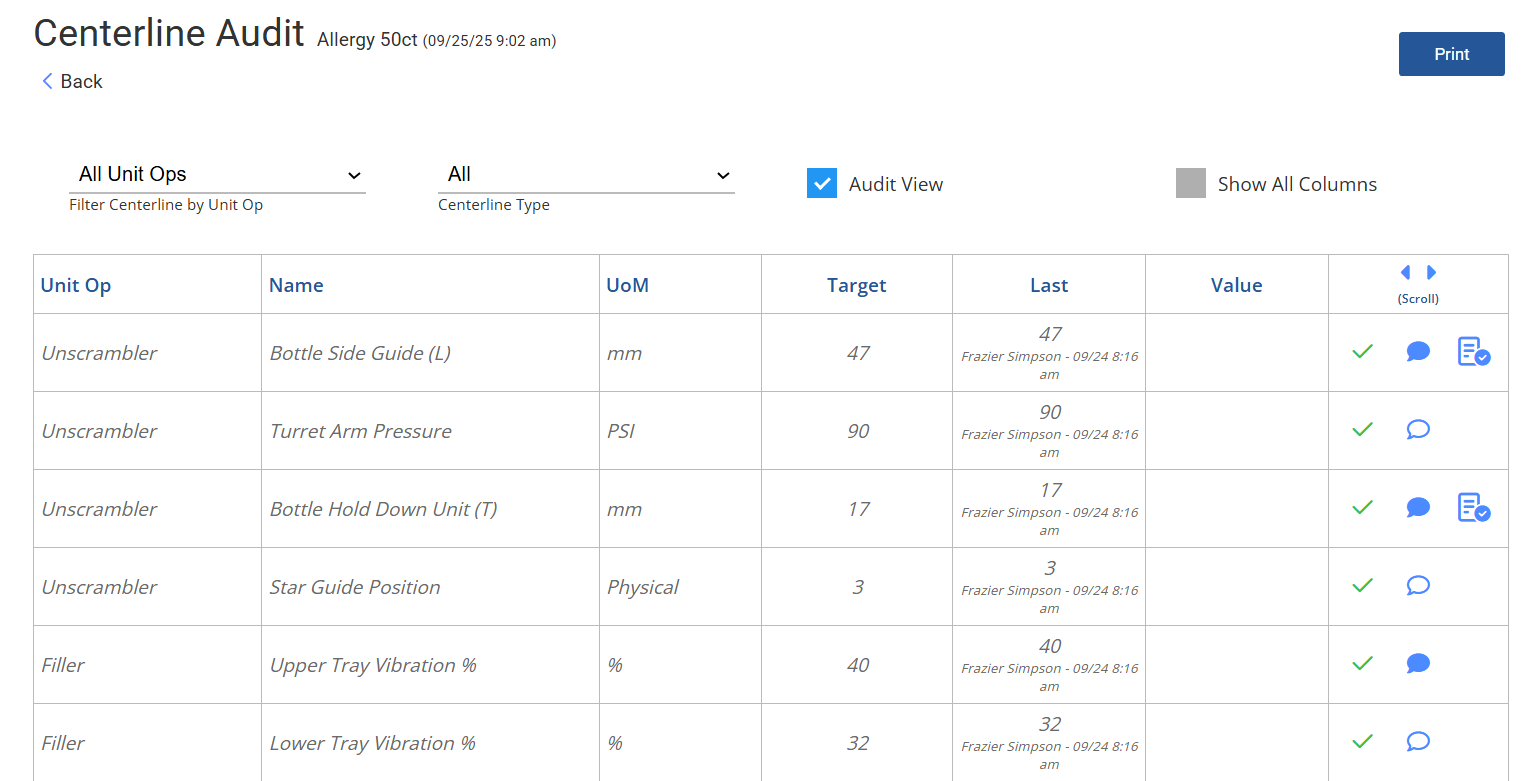

Centerline Audits with Support

Teams get the resources they need to run equipment right. Every setup parameter is clear, deviations can be explained, and standards from the Knowledge Base are one click away.

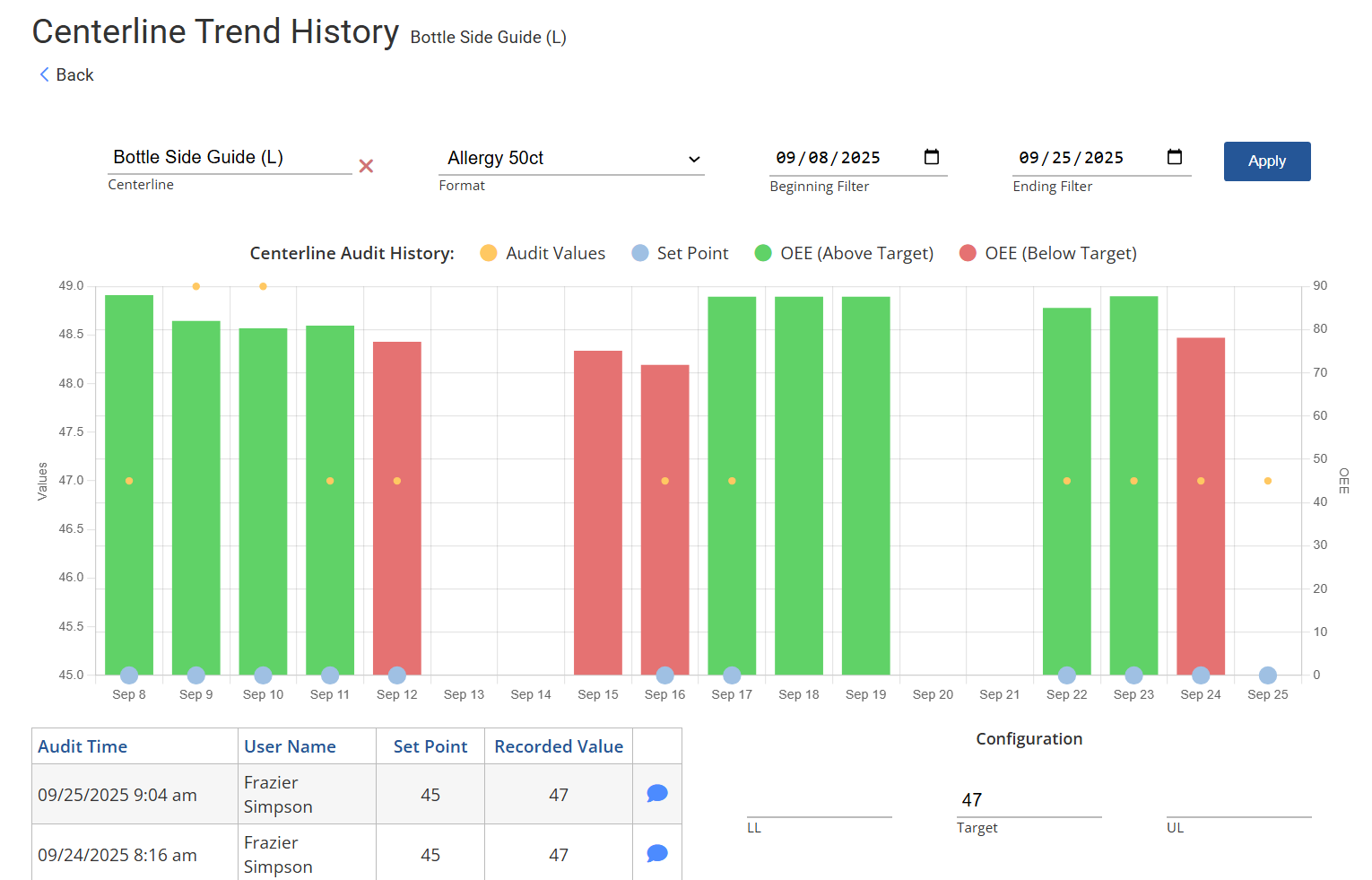

Compare Trends & Performance

Trend histories compare actual audit values against targets and correlate them with performance, so teams know exactly where reliability starts to slip.

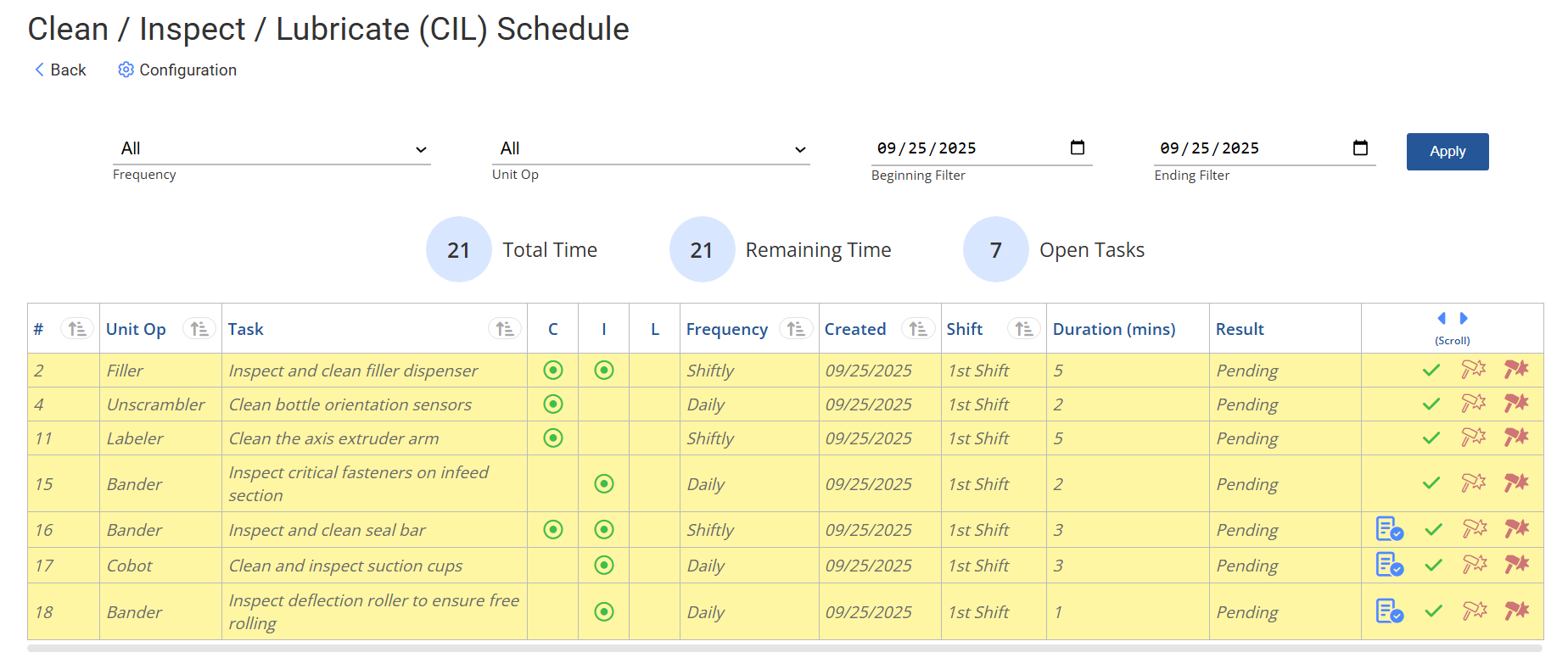

Keep Equipment in Base Condition

CIL tasks keep equipment in base condition shift after shift. Linked standards ensure inspections, cleaning, and lubrication are always done correctly and consistently.

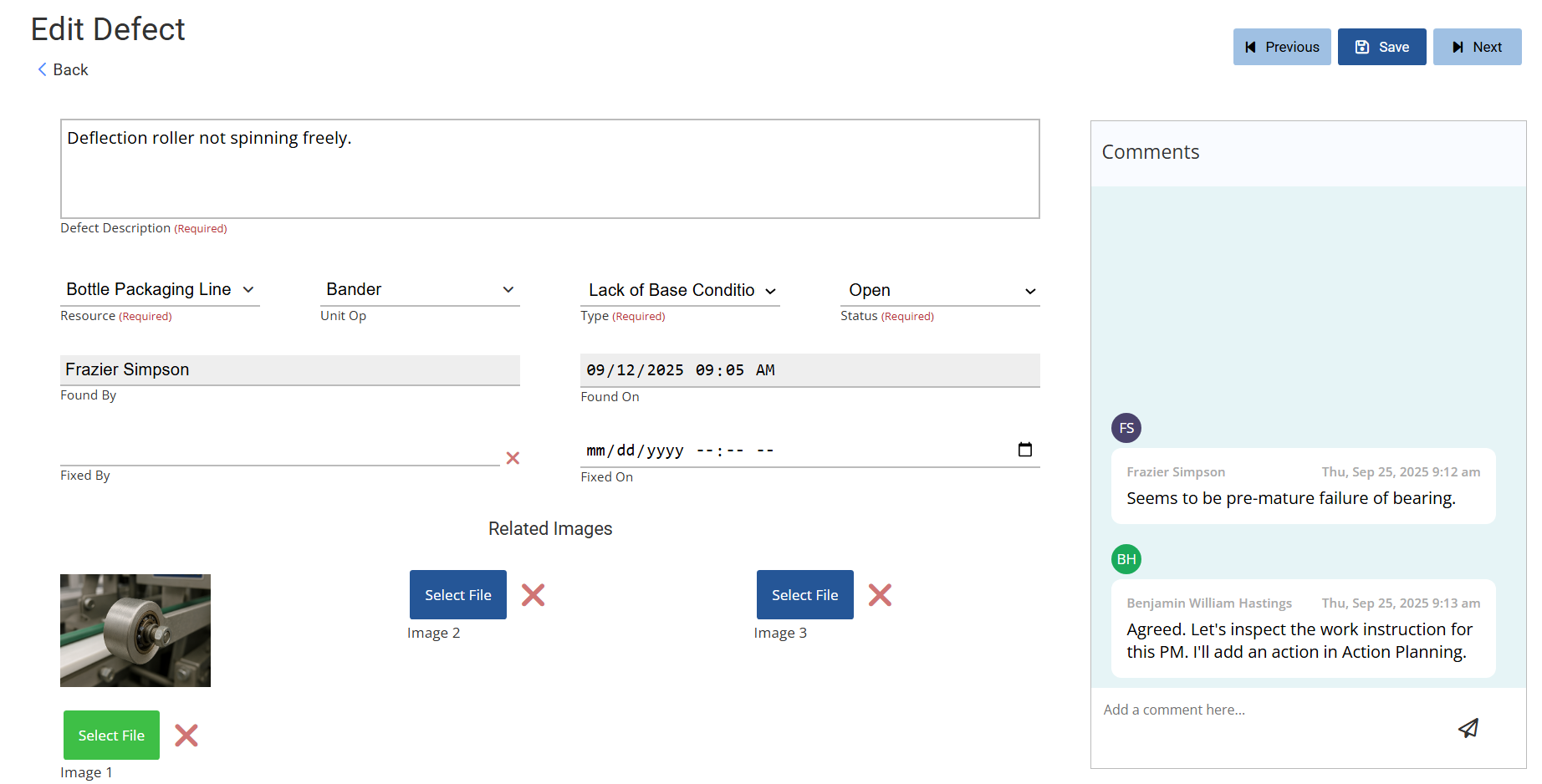

Defects Captured and Managed

Operators report defects on the spot, attach photos, and alert the right people instantly. Every defect has full visibility from submission through resolution.

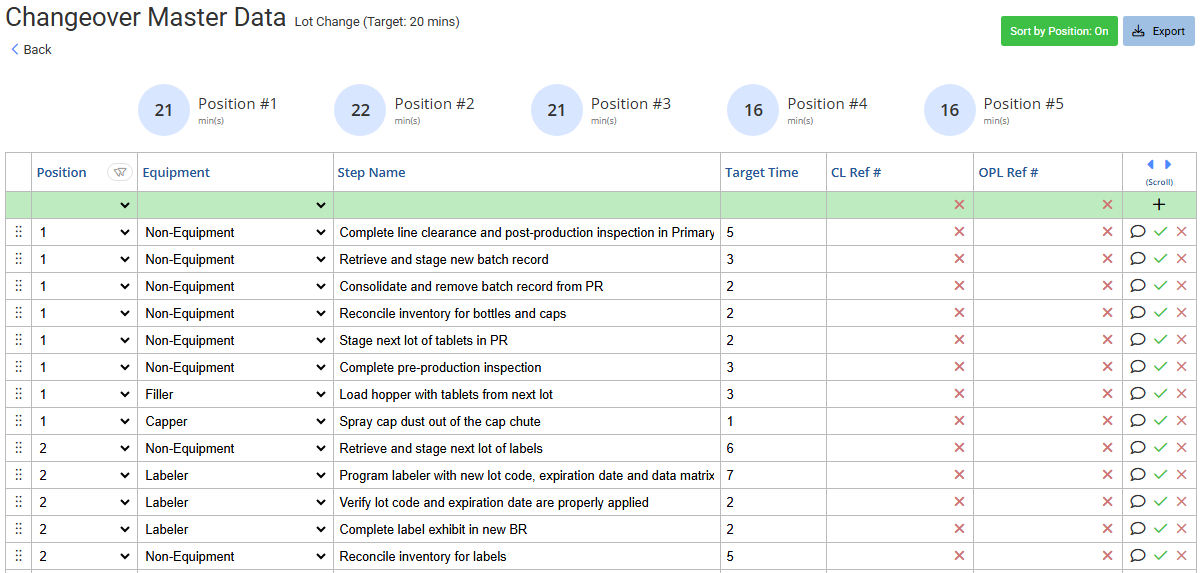

Changeovers with Standards Built In

Task lists are balanced across positions and linked to setup standards, one-point lessons, and target times — ensuring efficient, repeatable changeovers every time.

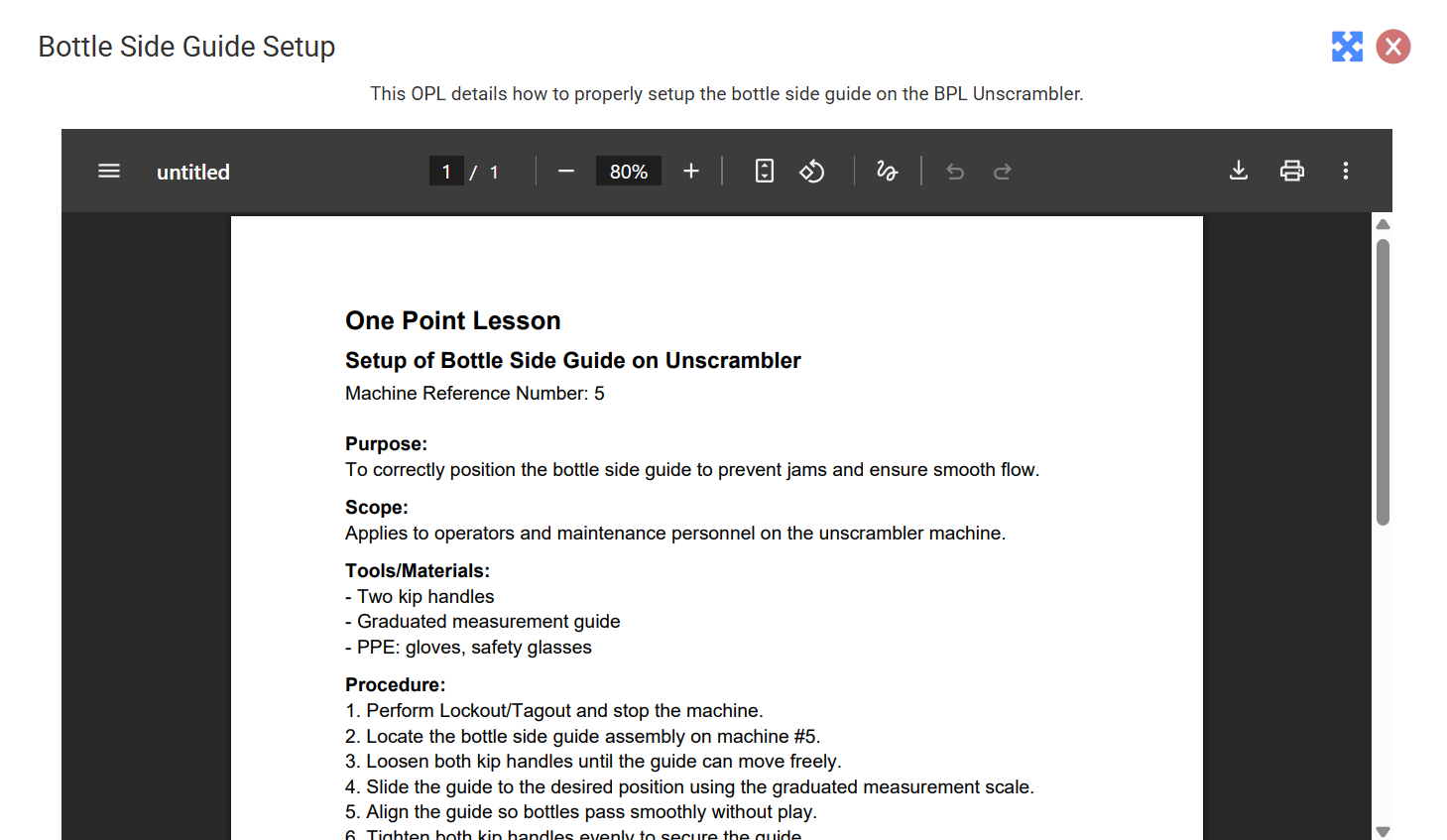

Standards at Your Fingertips

A centralized knowledge base houses every standard in photo, video, or PDF format. Revision management ensures teams always have the latest version.

MODULE COMBINATIONS

Autonomous Maintenance integrates with improvement and operational modules to create a comprehensive equipment care strategy that maximizes reliability and performance.

Action Planning

Connect equipment issues to structured improvement plans. Transform recurring maintenance problems into systematic action plans with root cause analysis and preventive solutions.

Operations

Align autonomous maintenance activities with operational schedules and production demands. Coordinate operator maintenance tasks with production planning to minimize disruption while maximizing equipment care.