Production Execution

Execute process-based production operations with real-time data capture, automated task generation, and seamless integration across all Plant Toolbox modules.

Process-Based

Device Integration

Auto Operations

Multi-Stage

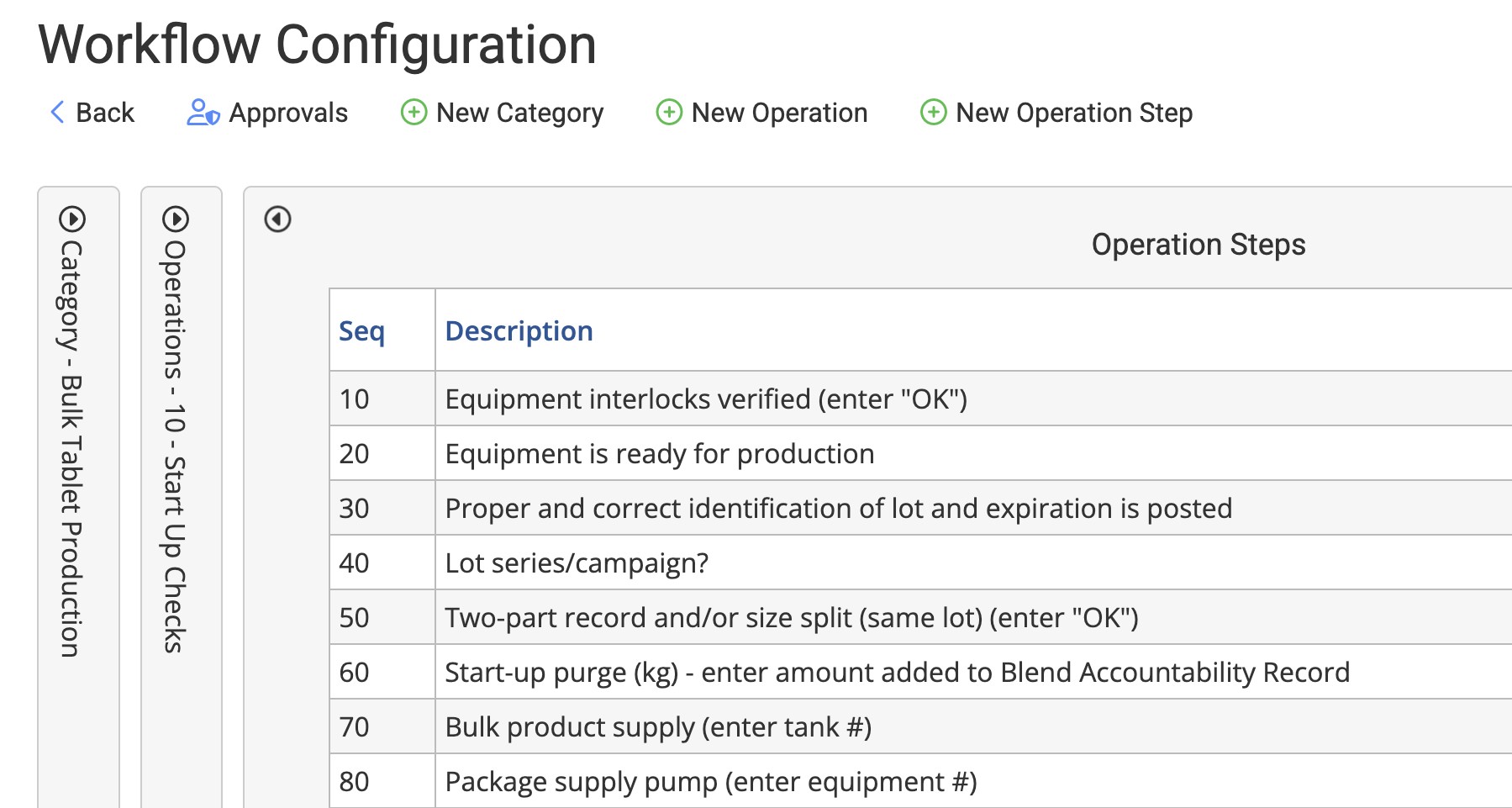

Process-Based Execution

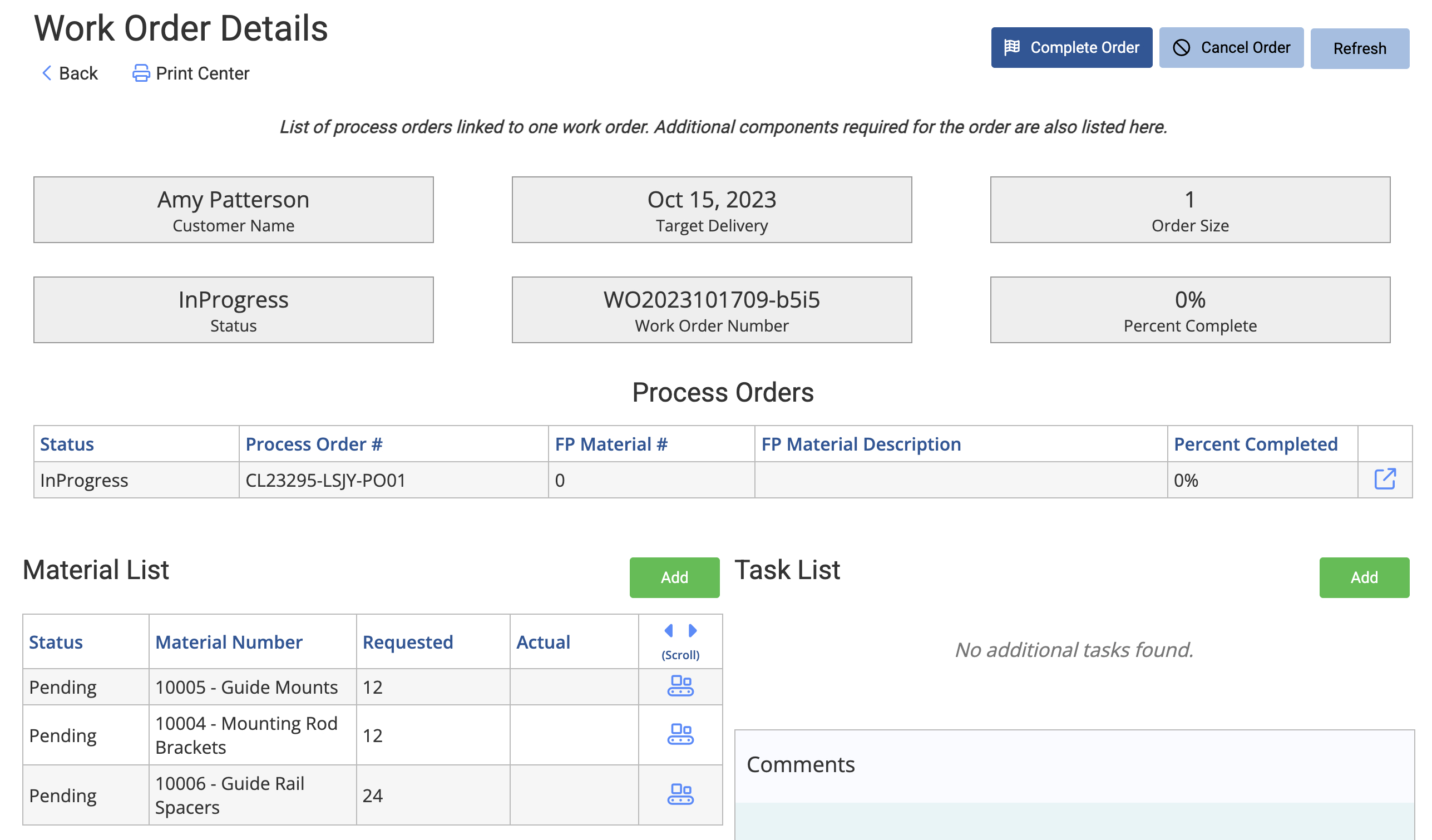

Define production processes that users execute against through generated orders. Store all relevant order information including quality metrics like fill weights, sample counts, and audit images. Model multi-stage processes across processing, packaging, and post-packaging operations.

Shop Floor Device Integration

Connect directly with devices on the shop floor to monitor and control production equipment. Track and adjust temperature settings, start and stop mixing operations, capture samples automatically, and gather real-time data from manufacturing equipment.

Inventory Manipulation & Control

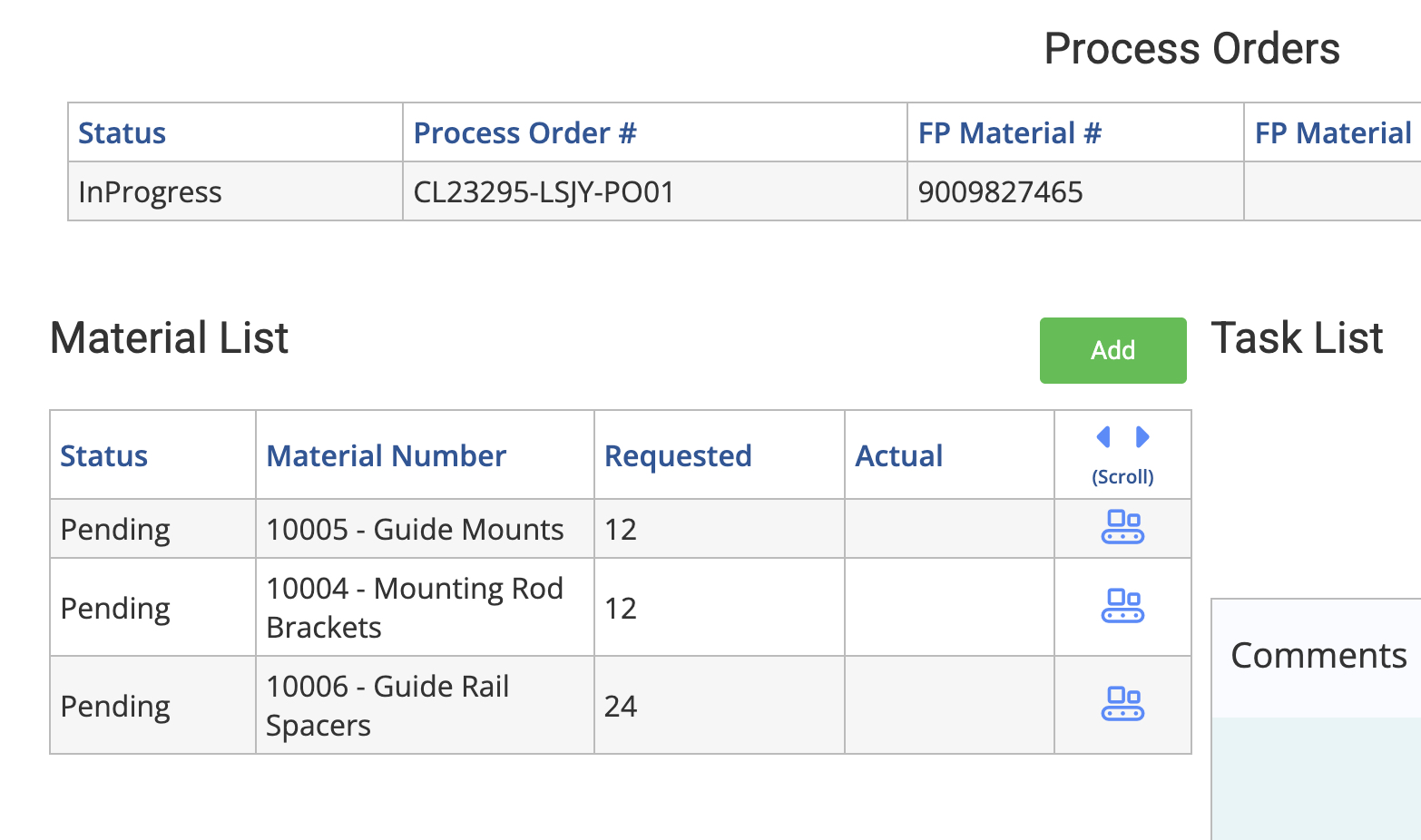

Manipulate inventory through production execution with automated consumptions, material movements, production reporting, and goods receipts. Track what materials go in and what finished products come out of each production order with complete traceability.

MODULE COMBINATIONS

Production Execution serves as the operational hub, pulling real-time data from and manipulating other Plant Toolbox modules to create a comprehensive manufacturing execution system.

Supply Stream

Generate production tasks automatically based on supply stream schedules. Convert scheduled orders into executable production tasks with proper sequencing, timing, and resource allocation aligned with your planning system.

Inventory

Connect to inventory to access real-time location and availability information for parts needed to complete tasks. Verify materials are available before starting production and know exactly where to find required components.

Operations

Communicate directly with devices on the shop floor through read-only or read-write connections. Monitor equipment parameters like temperature readings or actively control operations such as starting and stopping mixing processes.